DIY Plated Through Holes

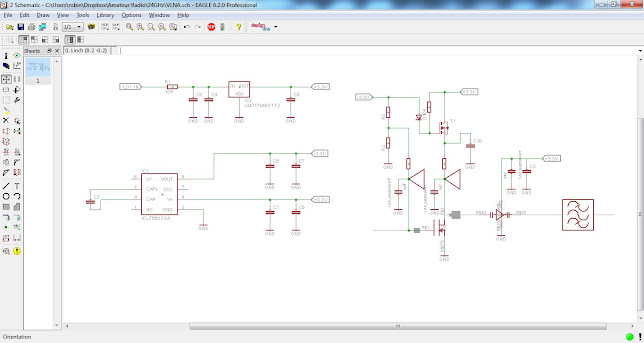

Here's a method I have used to produce high quality plated through hole PCB's in Rogers RO4003C material, although it should work on any double sided board. Unlike some of the commercial and other methods, this requires just 1 tank of fluid and the materials can be bought for around £20. First, why? A little introductory background. I packed away my home circuit board etching equipment (or more likely threw it away!) many years ago. For the last decade or more, the easiest and cheapest way of getting good quality double sided (or even multi-layer) printed circuit boards in FR4 has been to simply produce the Gerber files on your favourite PCB design package and send them off to China. You can get 5 boards made for less than £5, making them yourself is simply not worth it. I know, I know, giving money to China etc. The trouble is, FR4 is not really great for microwave. It has a high dielectric constant which can be quite variable depending on what particular board the supplier h...